Brass Ball Valve Series

Fire Fighting Water Flow Brass Ball Valve

- Brass Requested material

- Requested Logo

- OEM Package

- Good Lead time

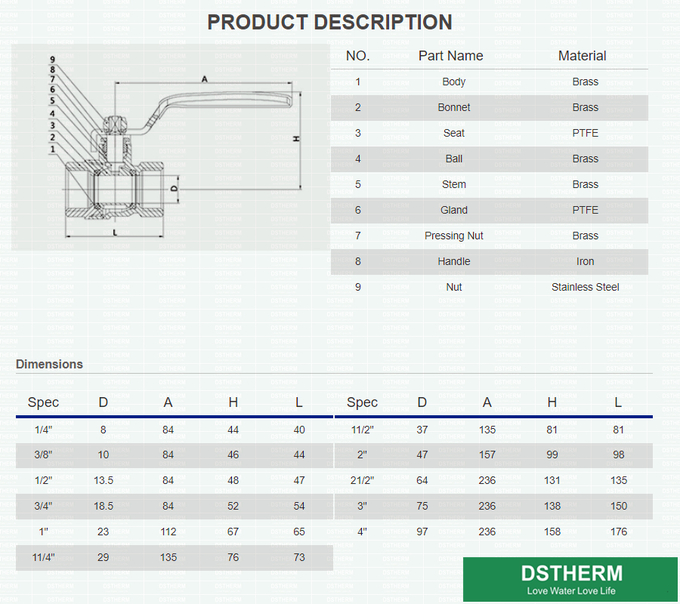

- Product description: Fire Fighting Water Flow Brass Ball Valve

Ball Valve

| Material | Brass Body, Brass Bonnet, Chromed brass ball, iron handle |

| Surface | Natural brass or Nickel plated |

| Size | 1/2"3/4"1"11/4"11/2"2"21/2"3"4" |

| Samples Time |

1) 2 days - For our existing samples for reference 2) 30 days - If new size, need make the new mould |

| OEM Acceptable | Yes |

| Service | 7*24 Hours |

| Packing Details | Poly bag, inner box, out carton( pallet) |

| Payment Term | T/T, L/C, WESTERN UNION |

| Delivery Time | 35-40 days after confirming the order |

| Minimum Order Quantity |

2000-3000 Pieces |

|

Item: Ball Valve Size: 1/4" - 4" Brass material: 59-3 Connection Type: Female BSP x Female BSP Handle Material: IRON / AL Handle Type: Lever Stem Type: Blowout Proof Stem Material: Brass Seat Material: PTFE Body Seal Material: PTFE |

Ball Material: Chrome Plated Brass Valve Basic Body Material: Brass Surface Treatment: Nickel Plating Application: Can be used for oil & petroleum, and water Max. Temp: -20°C to+120°C Working Pressure: 25bar/362.5psi Port: All Features: Full Port for Maximum Flow Rate Standards: EN13828 |

Advantages

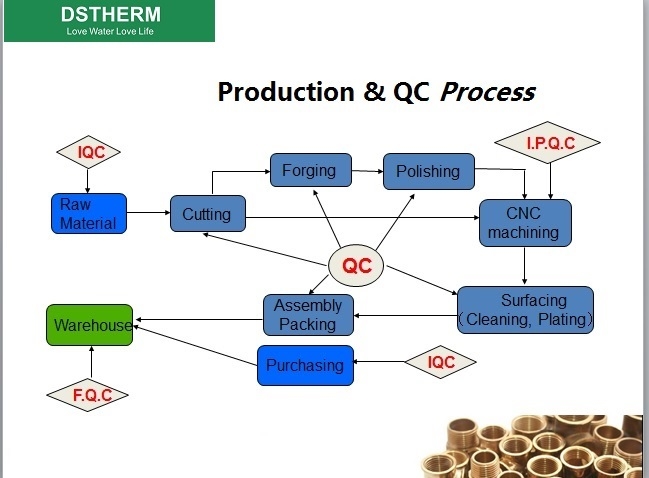

1) Fast Material Supply.

2) Every valve goes through a six-step QC process before delivery.

Material Control, Machining Quality Control, In-coming Material Inspection, Assembly Line Quality Control, Leakage Testing, Final Inspection Before Delivery.

3) 100% Leakage Test.

4) Strictly and perfect management in production.

5) Guarantee Quality In Competitive Price.

6) On-time Delivery.

7) Complete R&D facilities and Excellent team.

8) Annual R&D projects reach the number of 100.

9) Have rich experience and strong ability to develop new products.

QC:

· We promise to supply you high quality and durable goods for you.

· Our worker will check every accessory before hand-assembled.

· Our quality inspector will check every product one by one before packing.

· Regular checking on line from production in each workshop

Production step :

1) purchasing the material and forged the semi-products .

2) processing the semi-products in workshop .

3) assembling the goods .

4) testing the sealing in pressure and checking quality of the goods

5) package

6) deliveing the goods on time .

Package:

1) the package standard : standart export carton, box .

2) if customer has special requirement. it is available to provide the colorful package against the design of customer.

Categories

- Brass Inserts

- Brass Fitting Series

- Garden Hose Pipe Fittings

- Brass Flared Fittings

- Brass PE Compression Fittings

- Brass Prefilter

- Brass Manifold

- Brass Angle Valve Series

- Brass Gate Valve Series

- Brass Ball Valve Series

- Brass Check Valve Series

- Brass Bibcock Valve Series

- Brass Lock Valve Series

- Magic Megnetic Floor Drain

- Faucets Series

- Sink Drainer

- Stainless Steel Fitting Valve

- Hot Products

Latest News

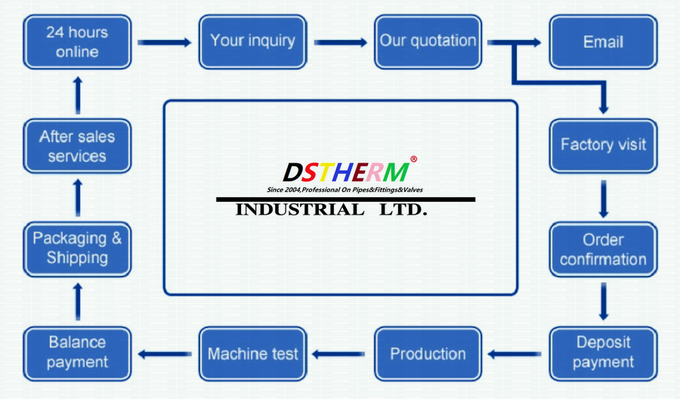

Contact Us

Contact: Johnson Yuan

Tel: +86-21-51316758

Phone: +86-13801911292

Email:dstherm@dstherm.com

Email:dstherm@gmail.com

Add: Headquarter:Building No.3 Yuanjiang Road No.3599 Minhang District, Focus Industrial Zone Shanghai China

Johnsonyuan

Johnsonyuan